HOME ALONE

While I was in Vermont, sipping my coffee in front of the fire, losing at Rummikub, and soaking in the beauty of the cabin (and my sisters), Gary was back in Montrose working hard on the A/C installation. And I mean busy! Â The supply damper controls arrived (which allows each room to control whether or not they get air conditioning), so he was able to get those installed in the attic. Â His first shipment of thermostat/control wire also arrived and he was able to start working on running and connecting the over one mile of wire that will supply power and smarts to the 5 units (and 23 rooms) on the second floor. Â Of course, he had to build a control panel both in a central location in the office along with smaller panels at each of the units.

So he was pretty darn busy while I was away.

SHE’S BACK!

But still, he did miss me! Some jobs just call out for two sets of hands. We got right to work on Wednesday morning connecting the black flexible duct to those supply and return dampers on the duct “runs”.

And that worked great with someone on the front and someone on the back. Someone was doing the actual attaching while balancing on floor joists and standing in the insulation, and someone was handing the the supplies to the guy in the respirator.

I guess you know now who was where. Â Tape, screw (with drill), wire-tie, wire-tie, wire-tie tightener/cutter gizmo, 3 screws, wire-tie, wire-tie, Â wire-tie gizmo. Â Repeat. Â Repeat. Â Repeat. I was invaluable. Â Like I said, he really missed me.

SLIPCOVERS

In the A/C business, insulation is King. Â And you never, never, never want to see bare, naked sheet metal. Â Never.

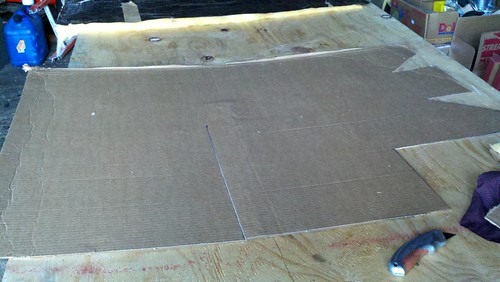

My assignment was to figure out how to cover these supplies (and the returns that you can’t see in the back of the duct work) with insulation. So I did what any respectable Sewing SOWER would do, I cut a piece of fabric, pinned away, and then transfered that to a big piece of cardboard.

Using that pattern, I cut out the pieces of fiberglass

so that I had the (mostly) correct size to cover each supply and return.

Then I repeated that 23 times. With gloves and a dust mask on. All good.

Today we started at 6AM with the insulation installation (say that five times fast) and got half of them done before the attic got too hot.

OK, so it’s not going to win any Better Home and Garden awards, but it definitely does the trick.

Kinda looks like a giant take-out burrito, doesn’t it?

HE’S A WIRE-Y KINDA GUY

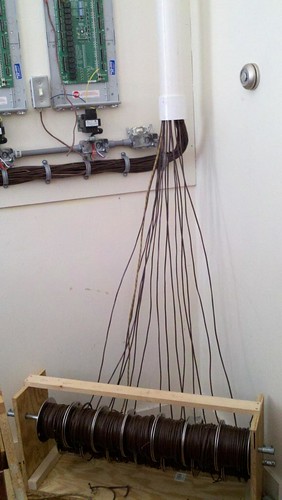

About that mile of wire. As I said before, Gary was very busy the week I was away. He not only installed that control board in the main office, but he ran a conduit pipe from the attic, through a room on the second floor down to the office so he could actually GET the wire from the units to the controls. By the time I got back he had already used up 14 rolls of wire at 250 ft./ea and was waiting for another delivery of more wire. When the new batch (another 14 rolls) arrived, we got to work pulling the final batches of wire that needed to get from the first floor to the attic.

First he would mark each wire for their different uses with colored electrical tape.

Then he would tie all the ends of the wires together and attach them to the rope that he’d threaded through the pipe from the attic.

(See how much wire has already been run upstairs? I told you he was busy while I was gone!)

Then he went up to the attic and began to pull up the wires.

Once he was sure it was all going smoothly, I joined him in the attic because these last two “runs” were the longest yet. So while Gary was moving it down the room,

I was doing the pulling!

Once we had enough length of wire pulled to get to the units, then we’d go back downstairs, he’d label the other end of the wires, attach them to the correct control board, and then I’d go back up to the attic and carefully pull up the slack. And while this seems like an incredible amount of wire, there is still more required. We (again, used so very loosely) need to do the wiring for the thermostats into each room and the dampers (again, one for each room). This was JUST the wire from the control boards to the units. I’m exhausted just thinking about all the different wires that need to go all those different places.

TOMORROW

Tomorrow we wrap up (get it, “wrap up”? :)) insulating the last batch of duct work. And that means – another early morning for the both of us.

Sweet Dreams, friends!